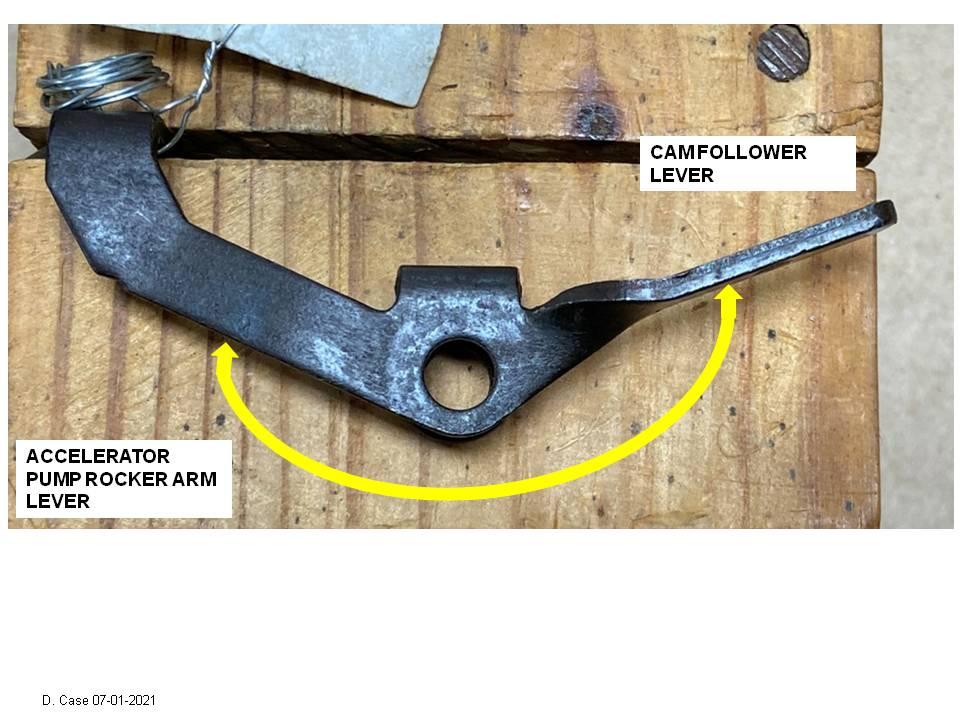

Bent Holley(R) Accelerator Pump Rocker Arms (Cam follower wear has been covered in another thread.): The pictures shown of are one of the most common versions of rocker arm used by Holley for 1960s 2V and 4V carburetors. The only way that the accelerator pump ?system? can work as design is for the all the components to be in proper working order. All the parts must be correct and in good condition but one that is often in terrible functional condition is the stamped steel rocker arm that follows the plastic cam on the primary throttle lever and translates the cam profile to the controlled drive of the accelerator pump assembled into the primary fuel bowl assembly.

Problem 1: The cam following lever has been bent in any direction or any way from the original design. I find levers that are:

1a: Still straight but bent up at an angle.

1b: Bent upward into a curve.

1c: Still straight but bent down at an angle.

1d: Bent downward into a curve.

1e: Straight but bent toward the center of the carburetor, which decreases the surface contact on the cam. In such cases, the edge of cams barley contacting the lever often wear away quickly and performance suffers.

1f: Straight but bent toward the primary throttle lever to the point of binding on the throttle lever.

1g: All kinds of combinations of 1a through 1f.

I have never measured the angle Holley produced in parts. I just keep known good, often a new old stock part, pieces on hand to use in comparisons. Most things that people do to change the cam follower lever can be corrected. The slide below show one of my comparison samples I keep. The angle marked is as Holley made it.

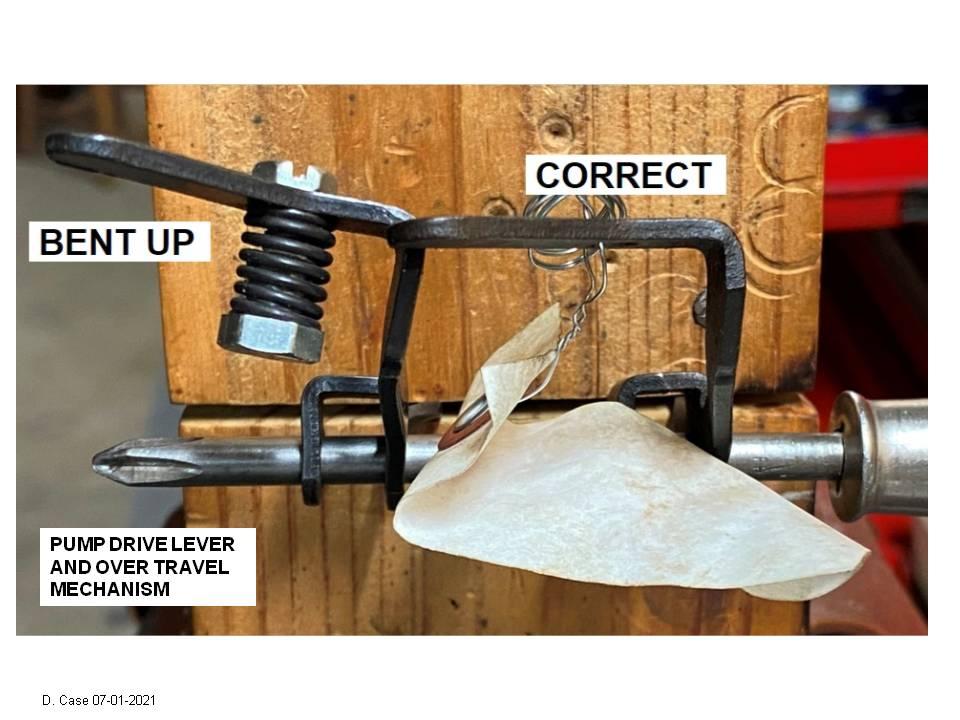

Problem 2: The lever end that drives the accelerator pump has been bent upward or downward. This is pretty rare but I recently repaired a carburetor a very famous carburetor restoration shop did and left the accelerator pump system in poor condition. The worst offensive was leaving a very bent rocker arm drive end bent. See image below. I could not adjust the over travel gap correctly with the lever in such a damaged condition. I was able to put the part back into good condition.