Not many seem to be doing their own carburetor work these days but of you do and you work any of the 1960s Ford-Holley carburetors with center inlet fuel bowls (a.k.a. LeMans or Le Mans bowls later) 1963-1969 you might be interested in this post. If you run one of the 427 Ford race models with all metal inlet needle and seats you might be more interested. Ditto if somebody uses all metal needle and seats in a 1965-1967 GT350 carburetor.

Ford Motor Company and Holley Carburetor Company both used carburetor inlet valves (a.k.a. needle valves) with a common all steel needle for many years. One particular needle was used with many seat designs. Many Ford vehicles of all types used the metal needle in the 1950s.

The Holley 4000 model used by Ford in the 1950s steel needle and a small orifice seat. When the Ford-Holley performance and racing carburetors for 427 engines came out the design was the same except for orifice size. When the R-3259 family was created for 289 engines the design was the same except the needles became tipped in synthetic rubber. The large 427 engine size orifice was reamed to 0.1280 inch nominal. The 289 engine size orifice was reamed to 0.1100 inch nominal. The "128" orifices were created by taking existing "110" orifices and enlarging them.

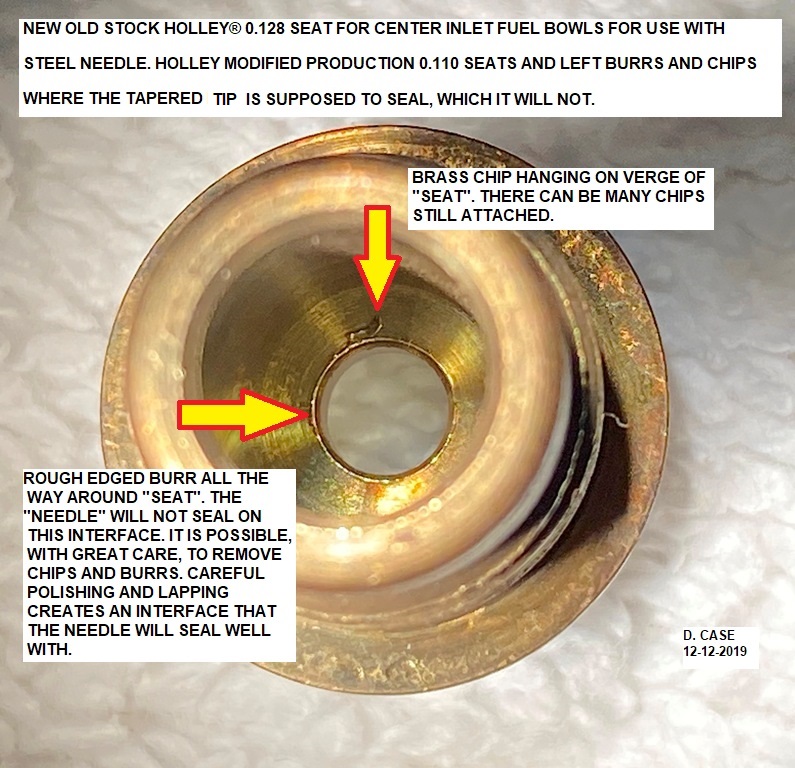

Now the problem. Every used and new old stock factory enlarged orifice I have held had ridges and or burrs left where the all metal needle was supposed to seal off. No surprise, they will not seal off against a rough seat. Ford and Holley both sold replacement needle and seat sets and both companies advised users that they were unsuitable for street use. What? Countless 1900s through the early 1960s street vehicles of all type using all kinds of carburetors used all metal inlet valve needle and seats successfully. Our 1930 Ford does for example.

The what was Holley's lack of attention to detail when existing "110" seats were enlarged to "128". I was sent a carburetor for a 427 Cobra engine that had just gotten a very expensive restoration by a world famous shop. When I bench tested it neither needle and seat was pressure tight for even a second. (Floats cannot control fuel level if needle valves leak fuel when they are supposed to be shut off completely. That includes not flooding the engine after hot shut down.) I found that each needle was really nice condition wise. I found each seat had significant defects in the seats left from reaming existing "110s". I reworked the rims of the orifices carefully, lapped the seats lightly, and reinstalled them. Now both would hold 6 psig of liquid tight pressure for more than half an hour. Really nice all metal needle and seats can go 45 minutes in static testing without experiencing any appreciable pressure decay.

I wondered if new old stock parts from the 1960s were as bad. I bought some new old stock Ford needle and seat kits for the 427 engine race carburetors. Yes, they were just as bad. A picture of a typical new old stock one is below.

If you are using a carburetor with center inlet bowls AND an all steel needle you should be aware of this.

PS Used GT350 valves and or modern aftermarket valves can have seats and or needles with all kinds of little defects that affect sealing. Last fall I serviced the GT350 carburetor for a local friend. When I tested the valves one leaked. I took both the seat and needle to the microscope. The seat was okay but the rubber tip of the needle had a diagonal slice in it. Something sharp had cut the rubber. I replaced that needle. The final assembly leak down test was fine then.